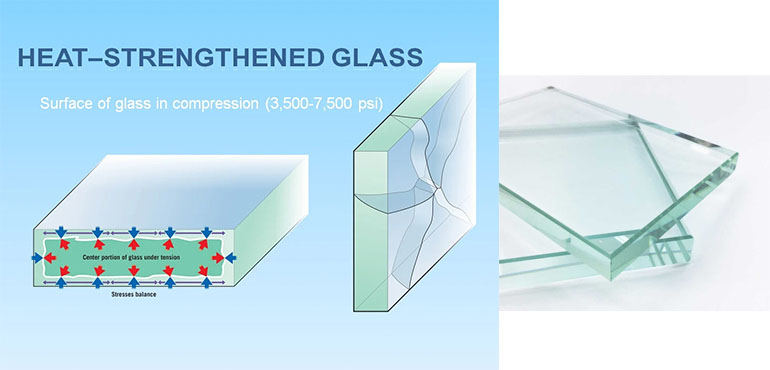

Heat-strengthened glass is processed with heat, which creates surface compression. There are two types of heat-treated glass, which are often confused with each other. Heat-strengthened glass and tempered glass are made in similar processes but offer slightly different results.

Heat-strengthened glass and tempered glass are both created with the same furnace and the glass heating to 1,200 degrees Fahrenheit. After it’s heated, quenching gradually makes the surface and edge compression this type of glass known.

Heat-strengthened glass has a slower cooling process, which means the strength of this glass type is weaker than tempered glass. However, heat-strengthened glass is still two times stronger than untreated glass.

This type of glass is generally used for regular glazing and offers additional strength and protection from thermal stress or load stress.

Heat-strengthened Glass Production Steps

-

Transfer the annealed glass into the furnace and heating it to its softening point. The softening point temperature is 1,200 Fahrenheit or 700 degrees Celsius.

-

The glass is then force cooled after heating. This is done at a slower rate than fully toughened glass.

-

The final product will have a surface compression of between 3,500 and 7,500 psi, making it twice as strong as regular glass.

-

However, it’s important to note this isn’t as strong as tempered glass, which is cooled at a much quicker rate.

-

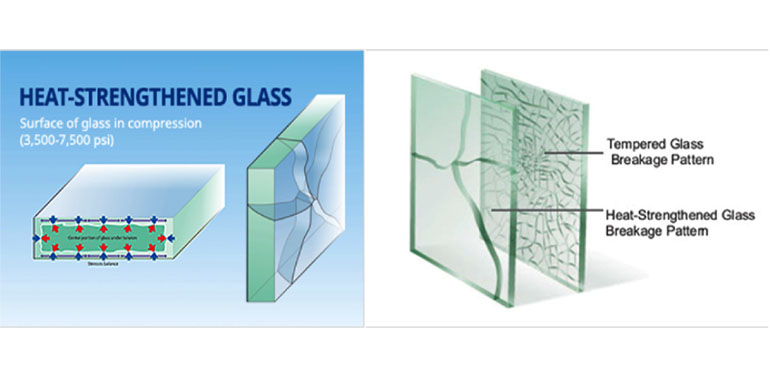

In the rare case that heat-strengthened glass does break once it’s installed, it generally looks a little more like annealed glass. It won’t shatter like tempered glass, and it may still create dangerous shards like regular glass.

-

Heat-strengthened glass has less distortion than tempered glass due to the speed of the cooling process. This means it is a great option where requires clarity and flatness for facade installations.

Properties of Heat-Strengthened Glass

-

Heat-strengthened glass, which may also be called semi-tempered glass, is used for a wide variety of applications. Due to its strength, it is often used in buildings that require additional protection compared to annealed glass.

-

The glass still offers the same flat and thick appearance as float glass, and the light transmittance is more similar to float glass than tempered glass. It has some of the great benefits of tempered glass but usually comes at a much lower cost than fully tempered glass.

-

If the heat-strengthened glass does break, it will crack radially from the source and generally keep the whole glass’s whole body in place. It’s often used in glass curtain walls for this reason.

-

Heat-strengthened glass has a slightly lower shock resistance than tempered glass but is double that of regular glass. The glass looks very smooth, like ordinary glass, and offers less optical distortion.

Quality Defects of Heat-Strengthened Glass

As with any type of glass that goes through a heating and cooling process, there are sometimes quality defects that occur as a result of this. These are some of the most common issues that arise with heat-strengthened glass.

1.Breakage During or After Installation

Breakages can also occur during or after the installation of heat-strengthened glass. There are multiple reasons for this occurring, some of which are directly related to the glass itself.

Thermal movement and air pressure changes can result in breakages and a lack of tolerance for movement from the glass.

As well as the glass itself, sometimes the frame will cause issues during installation, resulting in the glass shattering in the process.

2.Scratches

As with any glass, there is always the risk of scratches with heat-strengthened glass. While this glass is two times stronger than regular glass, when it’s placed in high-touch areas, there’s always a risk of scratches and chips occurring.

There are a few methods you can use on heat-strengthened glass to remove scratches, which are also effective on tempered glass. While they may not work on deep scratches, they are an excellent option for lighter scratches.

Firstly, baking soda and toothpaste are a great DIY option. You’ll make a paste with these two ingredients and water, and then apply it with a damp cloth. After rubbing it in a circular motion, you should hopefully see the scratch fade.

Nail polish is another option that people like to use for a quick DIY fix, and you will paint over the scratch with clear nail polish to fill it in.

Finally, metal polish is another solution, which you can rub on the scratches. However, don’t rub with too much force, or you could add additional scratches to the surface.

Of course, deeper scratches may need professional treatment or replacement. If that’s the case with your heat-strengthened glass, you’ll want to contact a professional for further assistance

3. Deformation During Production

Deformation can occur during the heat-strengthened glass production stage. It most often takes two different forms and can result in waves in the glass and an overall bow.

The roller wave or a dip at the edge is caused by sagging, which can occur during the semi-molten state. It will make installation and use of the glass almost impossible as it won’t have a flat surface.

A general bow, which causes the center of the glass to rise up, is caused by cooling at different rates or temperatures with the two sides of the plates that are used. This will also be unusable as it will be impossible to place into a frame.

Benefits of Heat-Strengthened Glass

-

As with any glass, heat-strengthened glass has its benefits. While it’s certainly not as strong as other glass types, such as toughened glass, certain aspects of the production process make it a highly desirable option in buildings today.

-

There’s no risk of spontaneous failure. It is a phenomenon that exists in tempered glass only.

- If the glass does crack for any reason, it will break in a way that’s more similar to annealed glass, and the glass won’t fall out of its frame or lamination.

-

It is a more cost-effective and safe solution than annealed glass or other glass options on the market today.

-

It reduces thermal breakage or damage from snow, wind, and mechanical loads.

-

Can be exposed to sunlight for a more extended period without concern, unlike regular glass.

-

A durable and robust option that gives buildings extra protection in comparison to basic glass options.

-

It still offers the same look like regular glass, and you’ll enjoy a high level of light transmittance.

-

It is an excellent option for glass curtain walls and other large building installations.

-

Less distortion than tempered glass. It is due to the slower cooling time during the production process.

Applications of Heat-Strengthened Glass

Heat-strengthened glass is used in a wide variety of buildings today. Although it can protect your building from thermal load and wind, it is still not necessarily strong enough to protect your property from natural disasters like other strengthened glass can offer.

Heat-strengthened glass is used in any structure where would use glass would be used. It’s often chosen by architects who are worried about their structure’s exposure to sunlight and heat, resulting in regular float glass breaking after an extended period.

Tinted glass and high-performance glass, such as low-E glass, can be processed to become heat-strengthened glass with the benefits of these additional properties. Therefore, it has hundreds of different applications in homes and properties around the world.

When you are concerned about higher wind, snow, or mechanical loads, heat-strengthened glass is an excellent option. It will also reduce your chance of thermal breakage, so it is often used in solariums or buildings featuring a large amount of glass.

For a building that faces west or south-west, this glass is often used in windows. Skylights and roof windows will also often feature heat-strengthened glass.

Heat-strengthened glass offers many benefits to property owners and is more affordable than many other glass options you may consider.

For more information about heat-strengthened glass and the benefits, it could offer to your property, don’t hesitate to contact us by email or phone. We would be happy to answer any concerns or queries you have about using this type of glass in future projects.